Powder Coating Supply Center for Fast Color Changes

Colo International Corporation Group Ltd.- Type:Coating Production Line

- Certification:CE

- Substrate:Steel

- Brand:Hicolo

- Coating:Powder Coating

- Airflow Direction:Cross-flow Type

Base Info

- Model NO.:CL-6000PC

- Heating Mode:Diesel

- Paint Mist Treatment:Dry-type

- Condition:New

- Use:Powder Supply

- Working:Automatic

- Frequencey:50-60Hz

- Delivery Time:15 Working Days

- Air Pressure:0.6-0.8MP

- Power:500W

- Power Supply Voltage:1p 220VAC (110V)

- Pump Quantity:16 Powder Pump at Most

- Transport Package:Wooden Carton

- Specification:1500x1200x130mm

- Trademark:HICOLO

- Origin:China

- HS Code:8424899990

- Production Capacity:30 Per Month

Description

Basic Info.

Model NO. CL-6000PC Heating Mode Diesel Paint Mist Treatment Dry-type Condition New Use Powder Supply Working Automatic Frequencey 50-60Hz Delivery Time 15 Working Days Air Pressure 0.6-0.8MP Power 500W Power Supply Voltage 1p 220VAC (110V) Pump Quantity 16 Powder Pump at Most Transport Package Wooden Carton Specification 1500x1200x130mm Trademark HICOLO Origin China HS Code 8424899990 Production Capacity 30 Per MonthProduct Description

Powder Coating Supply Center For Fast Color ChangesFeatures

1.The powder feed central system provides fast color change.

2.The automatic spray gun, various powder hoses, and injectors will stay clean automatically

during color change.

3.A filter system maintains a comfortableindoor environment by transferring dusts during cleaning.

4.It does not require cleaning when changing the powder coating box

5.The unit is fullyprogramable.

Applicated for the automatic coating booth

Flexible with its larger hopper, quick in color change, it produces great coating results in a convenient

modular concept with OptiFlow injectors

Automatic vibrating powder feed center parameters

| Power supply voltage | 1P 220VAC (110V) |

| Power | 500W |

| Gas pressure | 0.6-0.8MP |

| powder pump | 16pcs(max) |

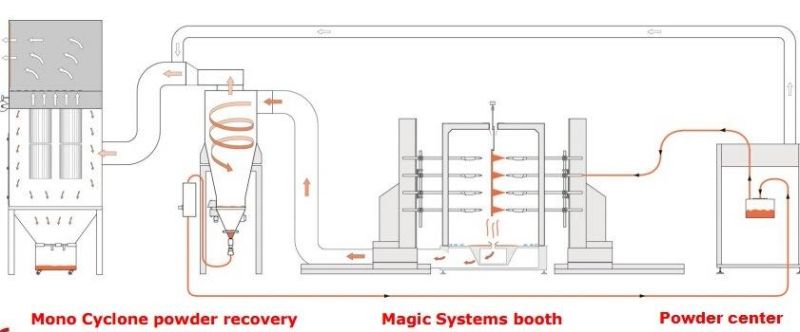

Image show

The automatic spray booth with reciprocator -automatic guns, various powder hoses,and injectors

will stay clean automatically during color change. A filter system maintains a comfortable

indoor environment by transferring dusts during cleaning.

Parts of the powder feed center:hopper,hose,pump

Hopper:the operator places the powder box under the powder hopper and activates the ventilation

of the OptiCenter housing

The recovery hose and pump are cleaned by compressed air pulses.

Side and front view

Powder Feed Center for fast color changes and improvement of productivity

The powder feed central system provides fast color change. The automatic spray gun, various powder hoses, and injectors will stay clean automatically during color change. A filter system maintains a comfortable indoor environment by transferring dusts during cleaning. The unit is fully programmable.

The powder position sensor will detect the position of the powder. A lack of powder will signal a warning which will fluidized the powder barrel :100 liter capacity. The cover extends the capacity and will prevent the powder from wafting.

Shake table: If you do not use the fluidized powder box, the powder can also be placed directly in the original packing carton shock stage. From there the powder can be pumped directly from the carton supply to the powder gun. It does not require cleaning when changing the powder coating box.

The automatic sifter contains a screen which removes impurities contained in the recovered powder.

Control System: Touch screen operator panel and keyboard input increase the supply of new powder automatically. Automatic matching of old and new powders together.

More details,please contact with us.