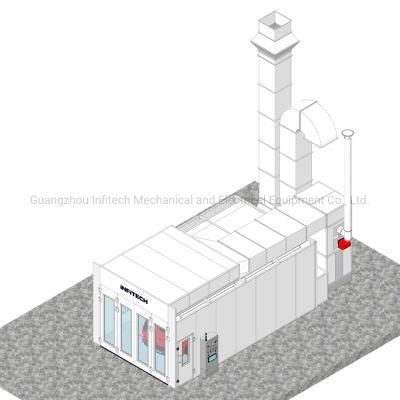

Rear Semi Downdraft High Efficiency Spraying Painting Room for Auto

Guangzhou Infitech Mechanical and Electrical Equipment Co., Ltd.- Type:Spray Booth

- Certification:CE

- Substrate:Steel

- Coating:Powder Coating

- Airflow Direction:Rear Semi Downdraft

- Heating Mode:Diesel

Base Info

- Model NO.:IT-701B

- Paint Mist Treatment:Dry-type

- Condition:New

- Plenum (Height):600mm

- Extraction:Through Exhaust Plenum Chambers

- Extraction Area:4.8m2

- Walls:50mm Rock Wool Walls

- Brightness:>1,000lux

- Intake/Exhaust Unit:Siemens

- Air Volume:18,000m3,H

- Empty Loaded Air Speed:0.45m,S

- Heats:158kw Heat Exchanger,

- Maximum Working Temperature:80 Celsius

- Controls:CE Standard

- Inverter:Schneider

- Voltage:380V, 50Hz, 3pH

- Rated Power:15kw

- Noise:<78 dB

- Transport Package:Cargo Loaded on Steel Frame Handled by Forklifts

- Specification:7000 X 4000 X 2800mm (L X W X H)

- Trademark:INFITECH

- Origin:Guangzhou, China

- HS Code:8419899090

- Production Capacity:1000 Sets,Year

Description

Basic Info.

Model NO. IT-701B Paint Mist Treatment Dry-type Condition New Plenum (Height) 600mm Extraction Through Exhaust Plenum Chambers Extraction Area 4.8m2 Walls 50mm Rock Wool Walls Brightness >1,000lux Intake/Exhaust Unit Siemens Air Volume 18,000m3/H Empty Loaded Air Speed 0.45m/S Heats 158kw Heat Exchanger, Maximum Working Temperature 80 Celsius Controls CE Standard Inverter Schneider Voltage 380V, 50Hz, 3pH Rated Power 15kw Noise <78 dB Transport Package Cargo Loaded on Steel Frame Handled by Forklifts Specification 7000 X 4000 X 2800mm (L X W X H) Trademark INFITECH Origin Guangzhou, China HS Code 8419899090 Production Capacity 1000 Sets/YearProduct Description

Rear Semi Downdraft High Efficiency Spraying Painting Room for Auto1.FEATURES

- Rear semi downdraft airflow with rear extraction

- Quality construction & Solid booth structure

- Excellent lighting system

- High efficiency generator unit, low running cost

- Easy-to-use controls

- Easy to install and maintain

2.SPECIFICATIONS

| ITEMS | SPECIFICATIONS |

| Model | IT-SUPER-701B car painting cabin |

| Application | For car painting and drying |

| Design standard | BS EN 13355: 2004+A1:2009 BS EN 60204: 2006+A1:2009 |

| Internal dimensions | 7000 X 4000 X 2800mm (L X W X H) |

| External dimensions | 9170 X 4110 X 3460mm (L X W X H) |

| Airflow | Rear semi downdraft |

| Plenum (height) | 600mm |

| Extraction | Through exhaust plenum chambers |

| Extraction area | 4.8m2 |

| Entrance door | 3400x2700mm (WxH), 1 set |

| Service door | 800x2000mm(WxH), 1 set |

| Walls | 50mm rock wool walls |

| Ceiling lights (LED) | 8 sets, each 6 X 18W, 864W total |

| Sidewall lights (LED) | 6 sets, each 2 X 18W, 216W total |

| Brightness | >1,000LUX |

| Filters | Bag filter, high efficiency ceiling filter, filter at exhaust plenum chamber, exhaust filter |

| Intake/Exhaust unit | Direct-type turbine fan, 2x5.5KW, SIEMENS motor |

| Air volume | 18,000m3/h |

| Empty loaded air speed | 0.45m/s |

| Heats | 158kw heat exchanger, RIELLO diesel burner G20 |

| Maximum working temperature | 80ºC |

| Controls | CE standard control box |

| Inverter | SCHNEIDER inverter as option |

| Voltage | 380V, 50Hz, 3ph |

| Rated power | 15KW |

3.DETAILS

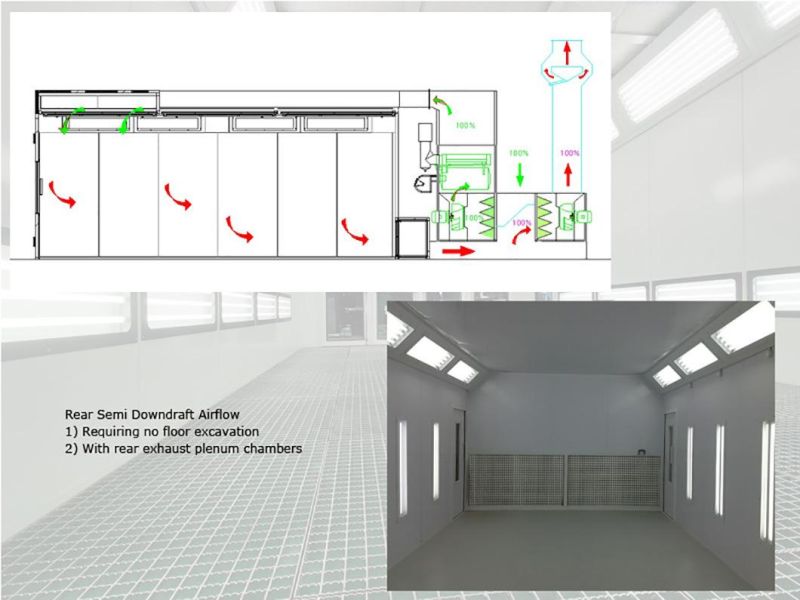

AIRFLOW

IT-SUPER-701B car painting cabin comes with rear semi downdraft airflow, requiring no floor excavation.

It has front roof intake air plenum. Fresh air enters the booth from outside the building, ducted through the roof intake filters, and is drawn across the working chamber, over the vehicle and into the filtered exhaust chamber at the booth rear.

Exhaust plenum chambers

Size: 4000*660*1200mm

Made of galvanized steel plate, with pleated andreae filters and fiberglass filters

OPTION

For other types of paint mist collection and extraction, please consult one of our experts for more information. We can cater to your individual needs.

- Extraction through metal basement

- Extraction through pits

- Wide front manual door (1 set): 3400x2900mm, with panic latch and big tempered glass windows

- Safety door (1 set): 800x2000mm

- Premium LED lamps, IP54 protection grade lighting fixtures

- Electric roller shutter door

- Explosion proof lighting fixtures

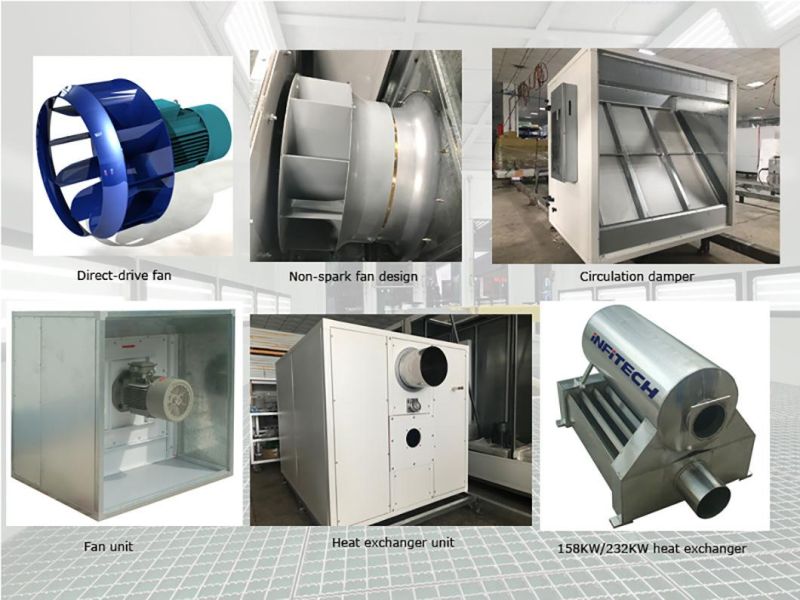

AIR HANDLING UNIT

- Direct drive big impeller fan (18,000m3/h air volume) & SIEMENS motor (2x5.5kw)

- Circulation damper for spraying and baking phase

- 158KW heat exchanger, RIELLO diesel burner G20 (one stage)

- Explosion-proof SIEMENS motor

- High performance low noise fans (Italian brand)

- Gas burner

CONTROL

- Basic functions: spraying, heating spraying, flash, baking, cooling

- Safety functions: emergency stop, over-heat alarm, failure alarm, fans interlock with heating system

- Main electrical components: SCHNEIDER brand

UPGRADE

- SCHNEIDER inverters

- Touch screen control panel

FILTERS

| Item | Specification |

| Pre-filter | Bag filter |

| Ceiling filter | High efficiency F5 grade filter |

| Filter at exhaust plenum chambers | Pleated andreae filter + Fiberglass filter |

| Extract filter | Activated carbon filter |

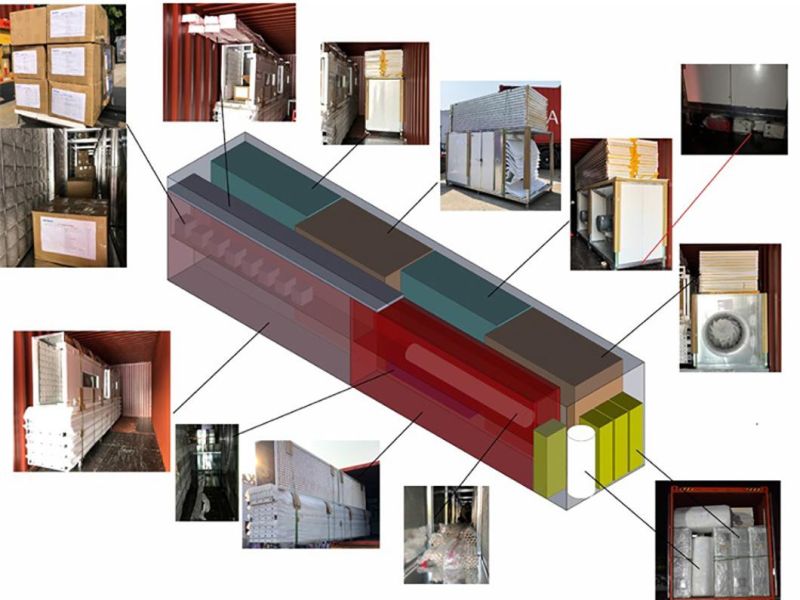

PACKING & LOADING

The painting cabin is generally delivered in various sub components palletized and in different packaging to be handled by forklifts. In some cases the components are systematized loose.

FAQQ: How many pieces of IT-SUPER-701B painting cabins can be loaded in a container?A: For IT-SUPER-701B painting cabin, 1x40HQ container can load 2 sets.

Q: How to make sure that the painting cabin is installed correctly?A: Complete set of installation materials (including installation drawing and electric schematic) will be supplied for guiding installation of the painting cabin. During the installation process, you can send us photos after work every day so we can check if the cabin is assembled correctly and find out problems and correct in time to avoid troubles.

Q: How long will I get the painting cabin after I order it?A: The production lead time for the standard painting cabin IT-SUPER-701B is 30 days after receiving the advance payment. The shipping schedule depends on which port the painting cabin is to be delivered to.

Q: How can I make sure the painting cabin quality?A: 1) We will send photos or videos of painting cabin projects that have almost same configurations as those of the painting cabin model we quote to you. So you can check the quality on photos or videos.

2) If we have painting cabin installations in your market, we will send the information to you and you can go and check.

3) We welcome your visit to our factory to do the inspection before placing the order or during the production of your painting cabin project.

4) During the production, we will send photos showing the production of your painting cabin project for your reference before packing and delivery.

Meanwhile, we have our own quality control to check the quality in the production process.

Q: How about the warranty?A: 2-year warranty for main components of the painting cabin from the date of acceptance. In cases that parts are damaged due to the product defects during the warranty time, we will replace by sending you new parts or pay back to you for having them replaced locally.