CE Standard Full Downdraught Spraying and Drying Cabin for Auto

Guangzhou Infitech Mechanical and Electrical Equipment Co., Ltd.- Type:Spray Booth

- Certification:CE

- Substrate:Steel

- Coating:Powder Coating

- Airflow Direction:Fully Undershot-type

- Heating Mode:Diesel

Base Info

- Model NO.:IT-1101

- Paint Mist Treatment:Dry-type

- Condition:New

- Airflow:Full Downdraft

- Plenum (Height):600mm

- Extraction:350mm

- Extraction Area:28m2

- Grids Carrying Capacity:900kg,Wheel

- Walls:60mm Rock Wool Walls

- Brightness:>1,500lux

- Air Volume:35,000m3,H

- Empty Loaded Air Speed:0.35m,S

- Heats:Direct Gas Fired Heating System

- Maximum Working:80 Celsius

- Controls:CE Standard

- Inverter:Schneider

- Stack Light:Yes

- Rated Power:28kw

- Transport Package:Cargo Loaded on Steel Frame Handled by Forklifts

- Specification:7000 X 4000 X 3000mm (L X W X H)

- Trademark:INFITECH

- Origin:Guangzhou, China

- HS Code:8419899090

- Production Capacity:1000 Sets,Year

Description

Basic Info.

Model NO. IT-1101 Paint Mist Treatment Dry-type Condition New Airflow Full Downdraft Plenum (Height) 600mm Extraction 350mm Extraction Area 28m2 Grids Carrying Capacity 900kg/Wheel Walls 60mm Rock Wool Walls Brightness >1,500lux Air Volume 35,000m3/H Empty Loaded Air Speed 0.35m/S Heats Direct Gas Fired Heating System Maximum Working 80 Celsius Controls CE Standard Inverter Schneider Stack Light Yes Rated Power 28kw Transport Package Cargo Loaded on Steel Frame Handled by Forklifts Specification 7000 X 4000 X 3000mm (L X W X H) Trademark INFITECH Origin Guangzhou, China HS Code 8419899090 Production Capacity 1000 Sets/YearProduct Description

Ce Standard Full Downdraught Spraying and Drying Cabin for Auto1.FEATURES- CE compliance

- Full downdraft airflow

- Solid booth structure

- 0.35m/s empty loaded air speed

- Direct gas fired heating system

- Long service time

- Lower operating costs

HIGHLIGHTS

Infitech high performance spray booth IT-SUPER-1101 comes with drive through entrance doors, shadow-free workspace and low noise efficient air handling unit and reliable and stable running. All these premium characteristics offer the ideal option for customers who attend to details and pursue perfect automotive paint refinish.

2.SPECIFICATIONS

| ITEMS | SPECIFICATIONS |

| Model | IT-SUPER-1101 Quality Automotive Spray Booth |

| Design standard | BS EN 13355: 2004+A1:2009 BS EN 60204: 2006+A1:2009 |

| Internal dimensions | 7000 X 4000 X 3000mm (L X W X H) |

| External dimensions | 7110 X 5760 X 4010mm (L X W X H) |

| Airflow | Full Downdraft |

| Plenum (height) | 600mm |

| Extraction | Through 350mm high raised basement |

| Extraction area | 28m2 |

| Grids carrying capacity | 900kg/wheel |

| Entrance door | 3400x2900mm (WxH), 2 sets, drive through design |

| Service door | 800x2000mm(WxH), 1 set |

| Walls | 60mm rock wool walls, 1.0mm thick substrate |

| Ceiling lights (LED) | 10 sets, each 6 X 18W, 1,080W total |

| Sidewall lights (LED) | 10 sets, each 3 X 8W, 240W total |

| Brightness | >1,500LUX |

| Filters | Bag filter, high efficiency ceiling filter, floor filter, exhaust filter |

| Intake/Exhaust unit | Direct-type turbine fan, 2x11KW, SIEMENS motor |

| Air volume | 35,000m3/h |

| Empty loaded air speed | 0.35m/s |

| Heats | Direct gas fired heating system, Eclipse burner |

| Calorific value | 400,000kcal/h |

| Maximum working temperature | 80ºC |

| Controls | CE standard control box |

| Inverter | SCHNEIDER inverter |

| Rated power | 28KW |

3.DETAILS

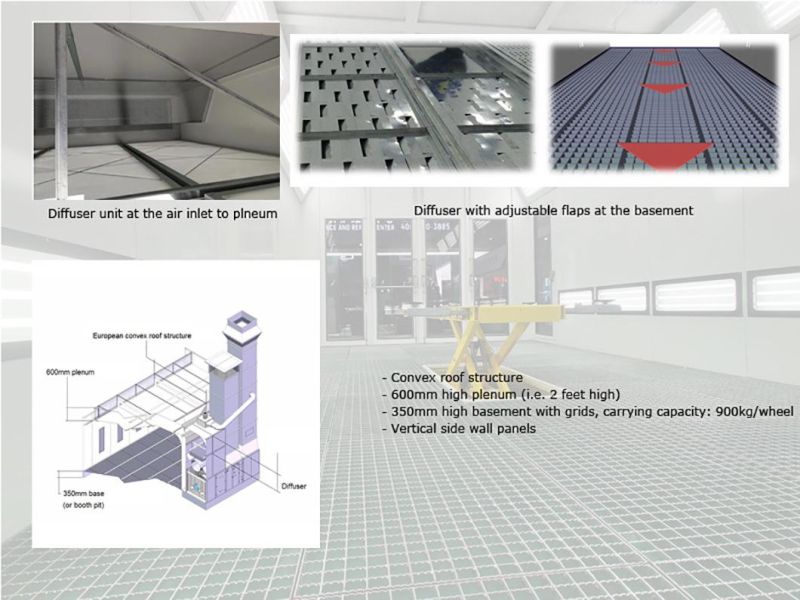

AIRFLOW & BOOTH STRUCTURE

INFITECH high performance automotive spray booth IT-SUPER-1101 is designed for premium downdraft airflow through the booth. The secret of well balanced flow owes to the 600mm high plenum, allowing for even air distribution from the plenum to the cabin.

After the air passes through the heating unit, it enters the diffuser (before it flows to the inside of the plenum), which provides important assistance to form balanced and stable air distribution in the plenum.

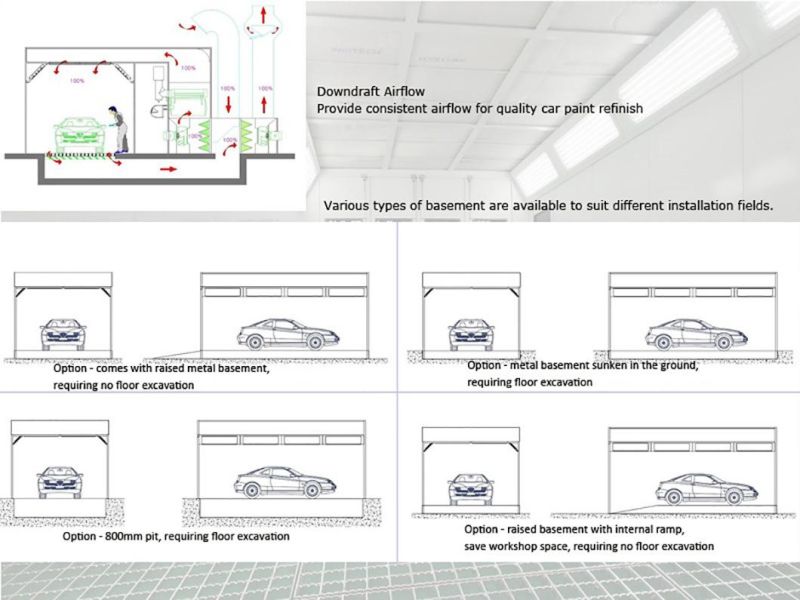

Air must be drawn evenly around the painted vehicle, and have the ability to be balanced. This is accomplished with the perforated plates with manual adjustment flaps, which are placed under the floor filter to balance the airflow from end to end.

OPTION

To cater to your installation fields, Infitech can provide various basement designs for paint mist extraction. Please contact us for more details.

DOORS & LIGHTS

- 4-wing product entry door: 3400x2900mm, drive through design, 2 sets (1 set at each end)

- Luxury service door with full size tempered glass window

- Inclined ceiling and horizontal sidewall lights create superb shadowless workspace

AIR INTAKE AND EXHAUST UNIT

- Italian brand low noise direct-drive fan & SIEMENS motor

- Cylinder-drive paint-bake conversion damper

- Direct gas fired heating unit, Eclipse direct fired burner

- 97% combustion efficiency

- Shorter process cycle

- Smooth and accurate temperature control

OPTION

- Conventional diesel burner RG5D

- Conventional gas burner RS5D

- Electric heating

CONTROL

- Basic functions: spraying, heating spraying, flash, baking, cooling

- Safety functions: emergency stop, over-heat alarm, failure alarm, fans interlock with heating system

- SCHNEIDER inverter control

UPGRADE

- Traditional control panel with manual buttons

- Automatic pressure adjustment

FILTERS

| Item | Specification |

| Pre-filter | Bag filter |

| Ceiling filter | High efficiency F5 grade filter |

| Floor filter | Fiberglass paint arrestor filter |

| Extract filter | Activated carbon filter |

FAQQ: Are you manufacturer?A: Yes. Infitech is professional manufacturer of CE standard spray booths.

Q: I need traditional gas burner instead of direct fired gas heating.A: That is okay. We can meet your requirements. We have RIELLO gas burner in options.

Q: How long is the warranty?A: 2 years.

Q: How do you pack and ship the spray booth?A: The spray booth is generally delivered in various sub components palletized and in different packaging. In some cases the components are systematized loose.

Q: How can I get assistance from you if I meet problems during the installation of the spray booth?A: Kindly be advised that you will be always provided with installation drawing, installation steps and wiring diagram to guide the installation.

In the meanwhile, if you meet any problem during the assembly, you can contact us in time. We will provide instructions and advice upon receipt of your request. If necessary, we will make video calls to you to check and guide the installation when the problem is complicated.

For big and non-standard projects, upon your special requests, we can send one or two technicians to guide the installation at the field.

Q: How to maintain the spray booth?A: Please follow the supplied product manual and maintenance manual for maintenance. Spray booth requires regular maintenance to ensure that it can work at its best performance.